Metalurgica Broal has 25 TON presses and forges of friction up to 150 TN for performing various mechanical activities always providing technical support to ensure the proper performance of its function matrices in cutting, stamping or forging according to work performed.

Forging is formed by a process of plastic deformation can be performed hot or cold and wherein the deformation of the material occurs by the application of compressive forces.

This manufacturing process is used to shape and certain properties of metals and alloys.

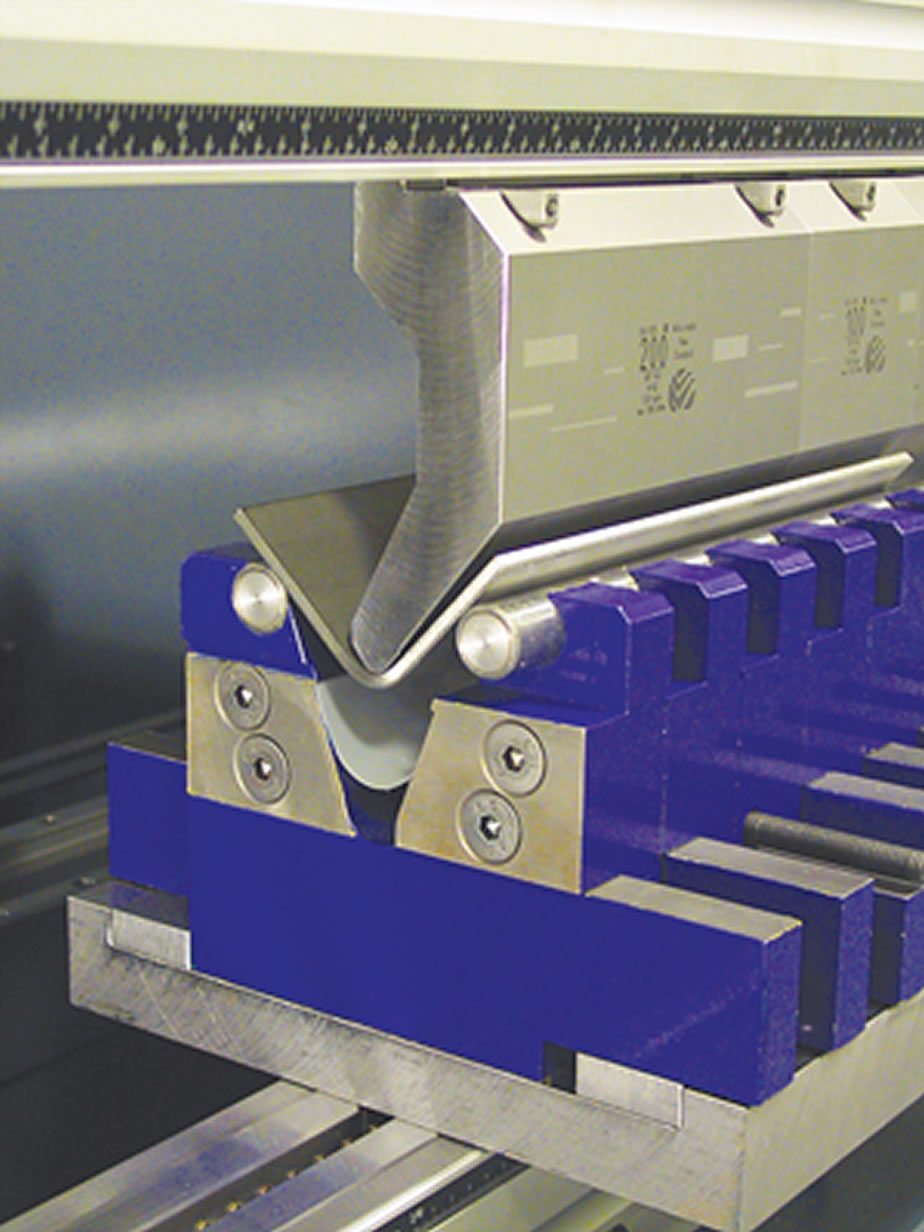

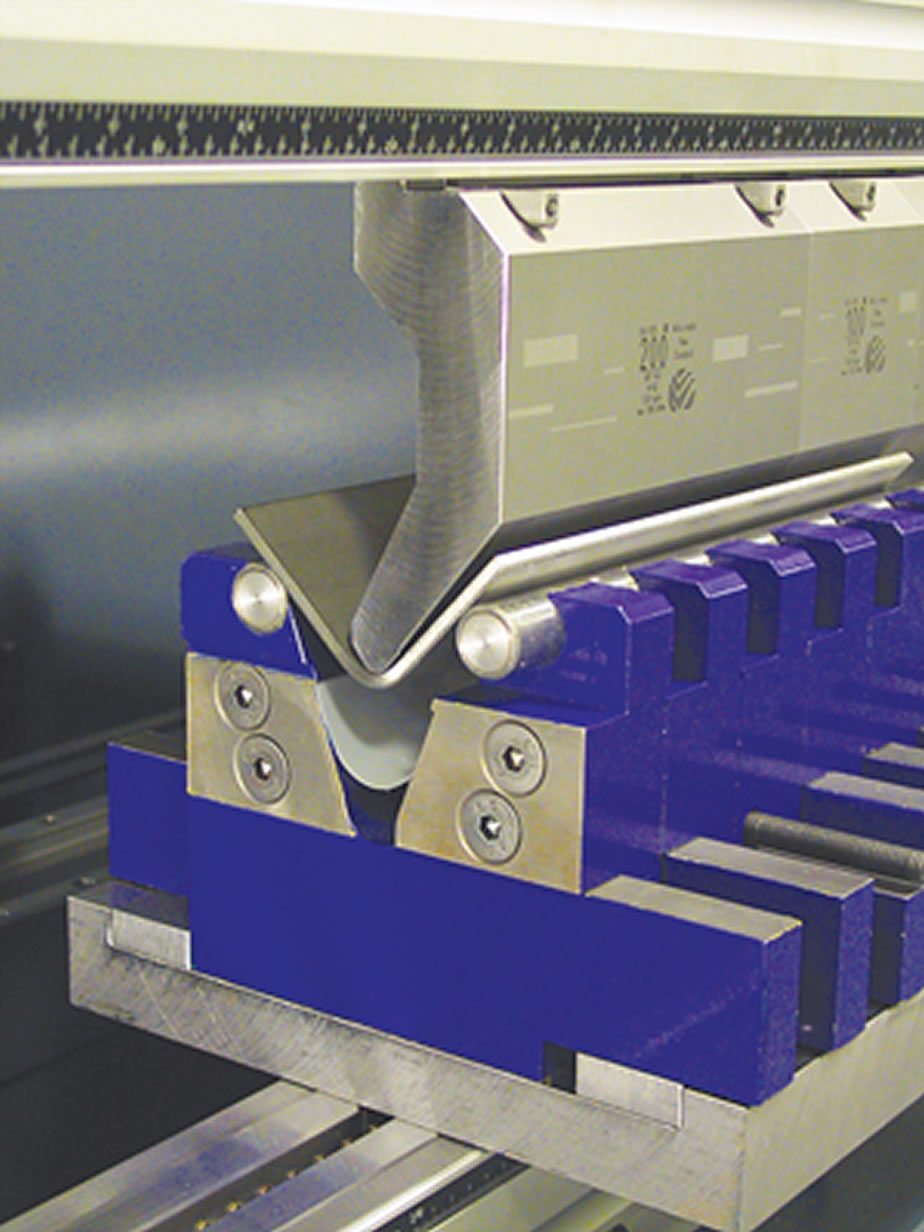

The deformation can be done in two ways: by pressure continuously using presses, or by impact using hammer intermittently.

The pressing is the process that acts on different materials, cold or hot, in any operation requiring strong pressure: packing, pressing, forging, pressing, extrusion, rolling and stretching.

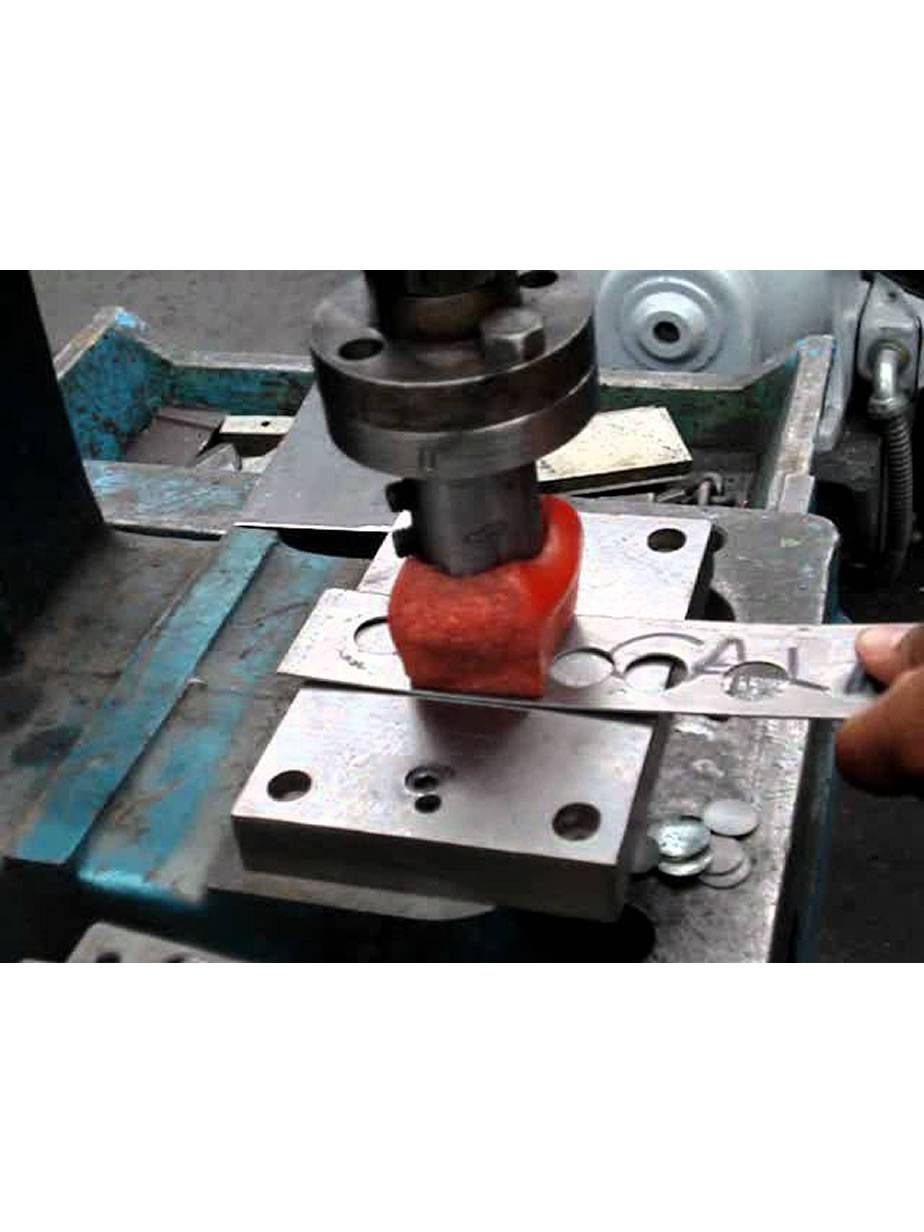

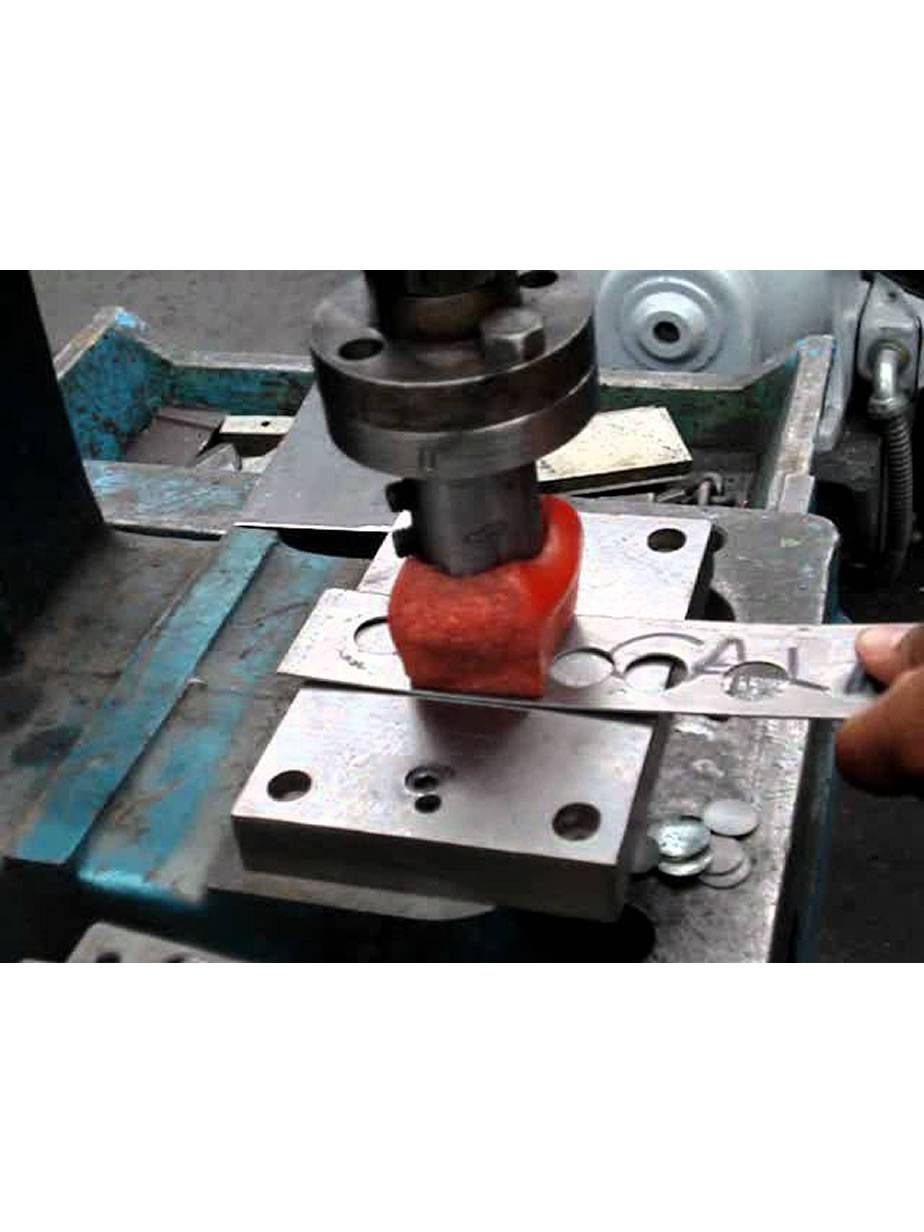

Simply pressing is performed by pressing a piece of metal between a punch and a die and to indent a white and give the product a rigid measure. Cans for food and beverage cans are the most common examples. and many more applications.

Its main advantage is that the pieces are almost one hundred percent of the nominal density of the material used, have a good metallurgical bond between particles, with grain structure and therefore good isotropic properties.